Back Again, and another Revelation

Thank you all for your patience. I’m back at the bench a bit.

We’ll be back to the vintage instrument in a moment, but this is what’s on the bench right now, so I’m sharing what’s happening with it.

The Hubbert Volksgurdy

Some years ago we upgraded a Volksgurdy built by Michael Hubbert with Schaller tuners. It was sold and came back to us with some cracks to be stabilized.

The first task is to remove the strings and take the wheel and shaft out. Here a couple of differences between our Volksgurdies and Michael Hubbert’s became apparent. The outside of tail bearing is smooth and cylindrical instead of threaded, so it’s held in with a screw. The other difference is that the shaft doesn’t have flats for a wrench, so the shaft has to be held another way to unscrew it from the wheel.

In an emergency (like escaping from a desert island) one can use Vise-Grips (TM) or similar instruments of torture to grip the shaft, but it’s not optimal because they dent the surface. (As a fiction writer, I’m now contemplating the situation in which one would need to be able to play the hurdy-gurdy in order to be rescued, and I’m coming up completely blank.)

A drill chuck is a better option. This one is the old one that came with the metal lathe back when we bought it to start building gurdies. It’s enough out of true that it’s not really good for using on the lathe, so it found new life doing this occasionally.

Here’s the instrument with the strings off and the wheel and shaft out. I’ve got a light rope inside to help with visualizing where to glue in the cleats. The easiest clamping system to use in this situation is a pair of rare earth magnets, and I need to be able to see inside to position the cleat.

I say “easiest” but that doesn’t mean “easy.” There are hazards to using rare earth magnets as clamps. There’s the frustration of trying to get the little piece of wood in just the right spot, in the right orientation, and doing it all fast enough that the hide glue hasn’t gelled yet. Then there’s the frustration of removing the magnet afterwards: we’re back to Saint Goldilocks with needing the tape to be tight enough to hold the cleat, but loose enough to let go once the glue is set. Meanwhile, the outside of the instrument needs to be protected from the ravages of the magnets.

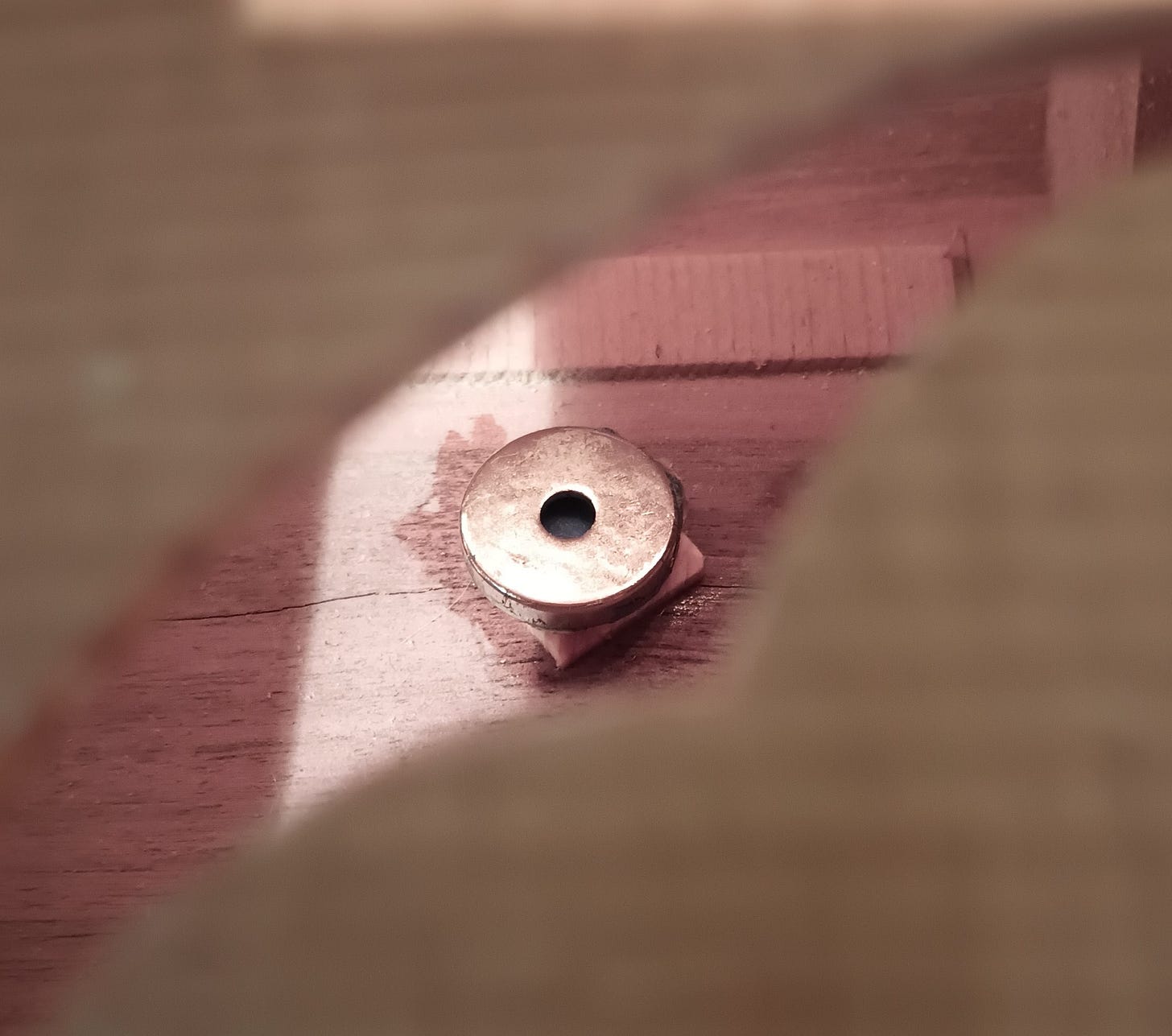

Here’s the view through the soundhole of one of the cleats being glued and clamped.

Finally it’s ready for the wheel to be put back in, except the shaft needs a little modification first.

Here I’m machining flats on the shaft for a 1/4” wrench. This will make it easier to remove the crank (it’s always best to remove the crank before storing the instrument) and also to get the shaft out for service.

The shaft and wheel are back in, and the new strings are on. Next will be shimming and tuning (and shimming and tuning, and shimming and tuning, and…)

Back to the Jomier, and a Deep Sigh of Relief

You’ll remember, perhaps, that the last time we saw the Jomier we had gotten the braces in and the soundposts in, and then I had the revelation that I’d made the wrong call on realigning the center brace. I concluded that (heartbreakingly) I needed to pull out the brace and fix it.

I slept on it for a while, and a few other things happened, and I really considered whether that was the right path. I have a tendency to second-guess myself, and to be a little too willing to come to the conclusion that I have made a mistake. So I took a step back and really looked at the data.

I placed this straight edge on the centerline and held it in place with the go-bar deck. Then I measured the alignment of the shaft. The head end is less than 1 mm off-center. Whatever measurement I had made earlier was incorrect, and the real data has shown that the shaft is close enough to being centered that I can proceed without any further ado.

I feel a lot of relief at this conclusion. It wasn’t that I wasn’t willing to do the work, or to take responsibility for making the mistake, because obviously I had already told you all that I was going to have to take a step back and fix the problem. I’m just looking forward to making progress.

The next steps will be to remachine the shaft and to remake the wheel.

Thank You

I’ve been feeling pretty down with the shoulder pain and the other negative things that have been happening. I’m very grateful to you all for your support through this time. I’m particularly grateful to my paid subscribers who could very reasonably have departed for greener pastures. Thank you for sticking with me even though I had nothing to show you.

Bright blessings on you all.